The geothermal fluids of the Aidipsos Springs, with temperatures reaching nearly 82°C, cause significant scaling problems in the boreholes of the “Damaria (G1)” spring (yield 19–20 m³/h) and the “Artemis” spring (yield 8–10 m³/h), both located within the premises of the ETAD S.A. Hydrotherapy Center. These carbonate deposits lead to the rapid clogging of the boreholes, which must almost annually be reconstructed to supply the nearby hydrotherapy facilities (approximately 600 m³/day). The current approach—constantly drilling new boreholes—results in (a) continuous financial burden and (b) further deterioration of the site conditions due to scattered flows of hot water escaping from various points within the Hydrotherapy Center area.

View of the ETAD S.A. Hydrotherapy Center grounds, showing travertine deposits, scattered hot springs, salt encrustations, and channels carrying hot water toward the cooling tanks (due to their high temperature) before it is directed to the facilities.

View of the ETAD S.A. Hydrotherapy Center grounds, showing travertine deposits, scattered hot springs, salt encrustations, and channels carrying hot water toward the cooling tanks (due to their high temperature) before it is directed to the facilities.

Following a request from the Head of the Aidipsos Branch of ETAD S.A., Mrs. Tarsa Gika, a team from the Hellenic Survey of Geology and Mineral Exploration (H.S.G.M.E.), consisting of Dr. Apostolos Arvanitis, Geologist and Head of the Department of Geothermal and Thermal Mineral Resources (GEOTHE), and geologists Panagiotis Vakalopoulos and Markos Xenakis—both members of the same department—visited the Aidipsos thermal springs to conduct an on-site inspection, assess the current situation, and hold the necessary discussions.

Following the visit, the above-mentioned geologists of the GEOTHE Department, in collaboration with Mr. Vasilis Zorapas, Head of the Department of Hydrogeology and Hydrology, submitted a proposal for the construction of water collection works (hydro-catchments) for the thermal springs located within the Hydrotherapy Center property.

The proposal was based on the following key parameters:

(a) The proposed hydro-catchment structures should be of a permanent nature, eliminating the need to construct new production boreholes almost every year.

(b) The proposed hydro-catchments should resist rapid clogging from scaling, while any carbonate deposits must be easily removed through mechanical cleaning (since, due to the therapeutic use of the hot waters, the application of chemical inhibitors to prevent scaling is not allowed).

(c) The proposed works should ensure an adequate supply of thermal water (approximately 600 m³/day for the ETAD S.A. Hydrotherapy Center and another 600 m³/day for distribution to around 15 smaller private hydrotherapy facilities) without the need for pumping. Given the high water temperatures, only special oil-lubricated pumps can be used instead of standard ones.

(d) The proposed hydro-catchment structures should minimize the scattered flow and uncontrolled discharge of thermal waters across the Hydrotherapy Center site.

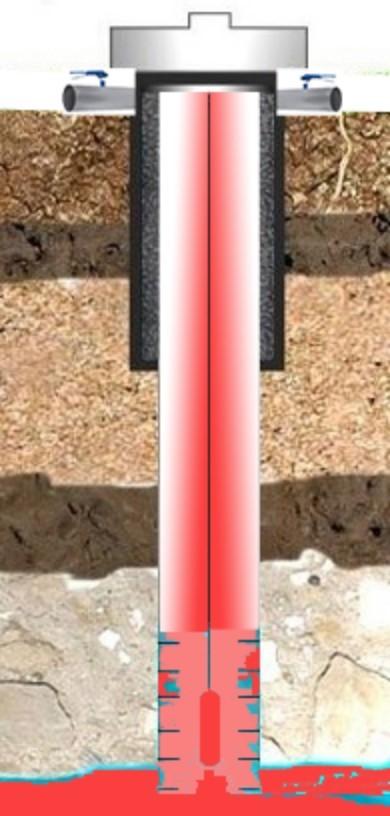

Taking all of the above into account, the proposal suggested drilling two (2) hydro-catchment shafts at the spring sites “Damaria (G1)” and “Artemis,” each with a bore diameter of approximately 1.60 m. Inside each borehole, reinforced concrete rings (1.25 m internal diameter, 1 m height, 20 cm thickness) will be installed in succession. The final depth of each shaft will be determined during drilling and will include the full thickness of the travertine deposits (up to around 20 m), possibly extending into the fractured bedrock, reaching the solid base and penetrating it by 1–2 m.

Scattered hot springs emerging from old boreholes within the grounds of the ETAD S.A. Hydrotherapy Center.

Scattered hot springs emerging from old boreholes within the grounds of the ETAD S.A. Hydrotherapy Center.

At the depth where the thermal aquifer is encountered, perforated concrete rings (6x6 cm holes covering 40–50% of the surface) will be installed to allow water inflow into the shaft. The upper part of the shaft will be sealed with a U-shaped reinforced concrete structure. The top ring will include two outlet pipes (made of suitable material) approximately 20 cm below the rim, forming a T-shaped outlet. Both pipes will have valves to control the hot water flow toward the existing distribution channels and to facilitate mechanical cleaning in case of future carbonate buildup.

This design allows water flow to be diverted from one outlet to the other when cleaning is required. Around the shaft, up to a depth of about 2 m, the annular space between the borehole wall and the concrete rings (estimated at 10–20 cm) will be filled with a special type of concrete to strengthen the structure and prevent lateral hot water leaks.

Alongside this proposal, the H.S.G.M.E. expressed its readiness to collaborate both in supervising the hydro-catchment works and in contributing to any future integrated management effort of the Aidipsos thermal springs, aiming for their optimal, rational, and sustainable use.